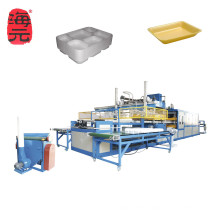

Aluminum Bending Machine

Basic Info

Model No.: ZYYX

Product Description

Model NO.: ZYYX Forging Forming Method: Cold Roll Forming Feature: Automation Warranty: 12 Months Advantage: Use Widely Guarantee Time: First Year Free, Lifetime Services Shafts for Rollers: Grand Twice, ID72mm Solid Steel Controlling System: Mitsubishi PLC & Converter Operation Language: English or as Per Client`S Required Cutter Material: Cr12 Mould Steel with Quench Treatment Trademark: Zhongyuan Origin: China Type: Rolling Machine, Tile Forming Machine Power Source: Hydraulic Pressure Certification: SGS, ISO9001, CE, SGS, BV, CE, ISO Customized: Customized Condition: New Hydraulic Press Power: 5.5kw Working Speed: About 1500-2000mm/Min or 4-5m/Min. for Option Machines Weight: About 9000kgs Rollers Material: No.45 Forged Steel with Hard Chrome Machine Type: Aluminum Bending Machine Specification: CE SGS BV HS Code: 84552210 Aluminum Bending Machine

This tile machine was design by 15 years experienced R&D members

1. Introduced Mitsubishi PLC with touch screen.

2. Need only one worker (minimum) to operate

3. Roller cover with 0.05mm chrome, ensure lifetime>10years

4. Cr12 mould steel cutter with quenched treatment. Blade with heat treatment.

5. Product automatic cut-to-length

6. First year free, lifetime services. Overseas service available

Parameter of tile forming machine

Process flow:

Decoiler -- Feeding & Guiding -- Roll Forming-- Pressing--Hydraulic Cutting - Product to Run Out Table

Packing:

1. One 40feet container for loading one set tile formign machine with mechanical decoiler.

2. Main formiong machine body and decoiler is load naked (tighten to container with steel wire rope).

3. Spare parts and operating tools are loading in tooling box.

Delivery:

about 60 days after received advaced payment

Contact us if you need more details on Aluminum Bending Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminum Forming Machine、Bending Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

This tile machine was design by 15 years experienced R&D members

1. Introduced Mitsubishi PLC with touch screen.

2. Need only one worker (minimum) to operate

3. Roller cover with 0.05mm chrome, ensure lifetime>10years

4. Cr12 mould steel cutter with quenched treatment. Blade with heat treatment.

5. Product automatic cut-to-length

6. First year free, lifetime services. Overseas service available

Parameter of tile forming machine

| Item | Specification | |

| Material | Type | Aluminum coils |

| Thickness(mm) | 0.4-0.6 | |

| Yield strength(mpa) | 235 | |

| Roller material | 45#Chrome steel | |

| Forming speed(m/min) | About 8 | |

| Output speed(m/min) | 0-3 | |

| Speed adjusting mode | AC Frequency | |

| Roller drive | Decelerating motor + Chain drive | |

| Cutting mode | Hydraulic cutting | |

| Cutter material | Cr12 mould steel | |

| Length measurement | Encoder | |

| Control mode | Mitsubishi PLC | |

| Operating mode | Button + Mitsubishi Touch screen | |

| Main motor power(kw) | 5.5KW | |

| Hydraulic power | 5.5 | |

| Components of machine | ||

| Decoiler | 1set | |

| Feeding & guiding device | 1set | |

| Main roll forming machine | 1set | |

| Hydraulic pressing system | 1set | |

| Hydraulic cutting system | 1set | |

| Controlling system | 1set | |

| Run out table | 1set | |

Process flow:

Decoiler -- Feeding & Guiding -- Roll Forming-- Pressing--Hydraulic Cutting - Product to Run Out Table

Packing:

1. One 40feet container for loading one set tile formign machine with mechanical decoiler.

2. Main formiong machine body and decoiler is load naked (tighten to container with steel wire rope).

3. Spare parts and operating tools are loading in tooling box.

Delivery:

about 60 days after received advaced payment

Contact us if you need more details on Aluminum Bending Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminum Forming Machine、Bending Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : More roll forming machines

Premium Related Products

Other Products

Hot Products

Grain Storage Silos Roll Forming MachineAluminum Spacer Bar with Factory PriceScaffold Platform Roll Forming MachineSolar Bracket of C Steel ChannelSolar Power Steels Roll Forming MachineGreenhouse Galvanized Gutter Roll Forming MachineHighfull Cable Tray Roll Forming MachineFull Auto Small-Sized Steel Frame Standing Seam Roofing MachineYIBO Machinery 2015 Steel Sheet Metal roofing tile stand seamer2015 New Model CZ profile chaneable Steel 350mm C Z Purlin Roll Forming MachineHigh class steel strip cz purlin roll forming machineLow price c shape steel cold forming koria. machineLow price z wave purlinLow price industrial machinery c purlinYibo Steel Structure Z Bar Roll Forming Steel Purlinpurlins