Stud and Track Roll Forming Machine

Basic Info

Model No.: ZT-006-06

Product Description

Stud And Track Roll Forming Machine

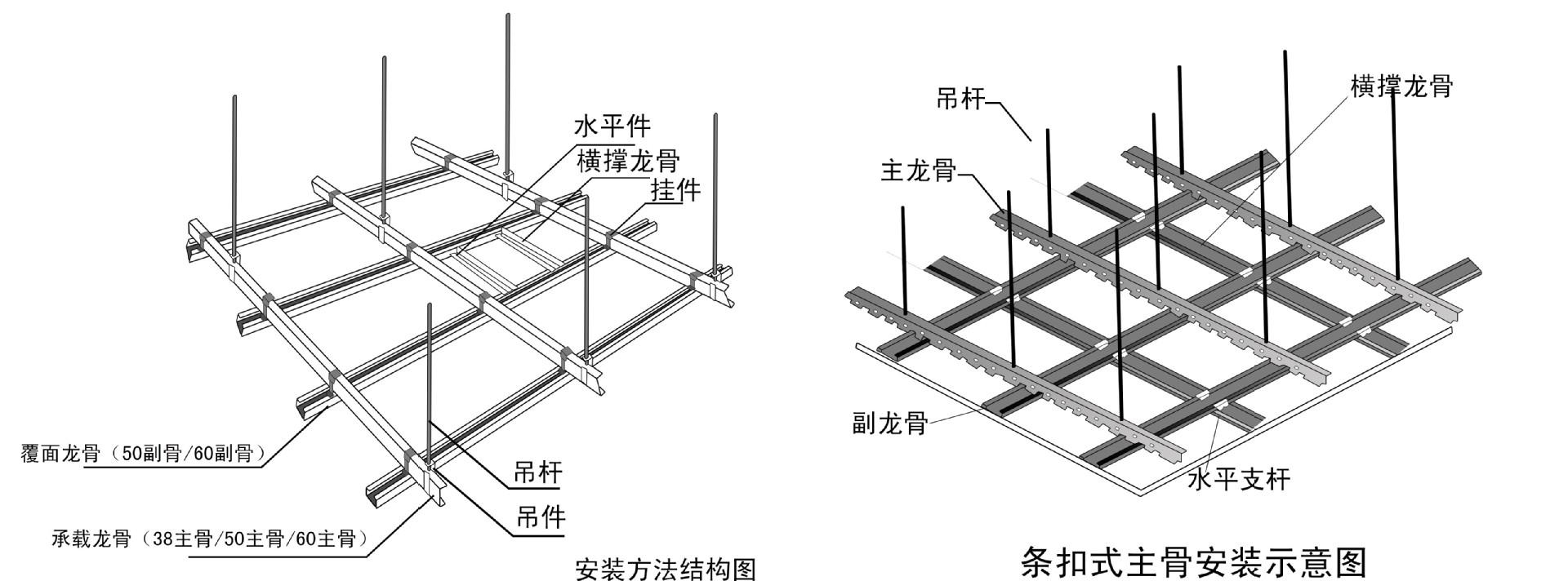

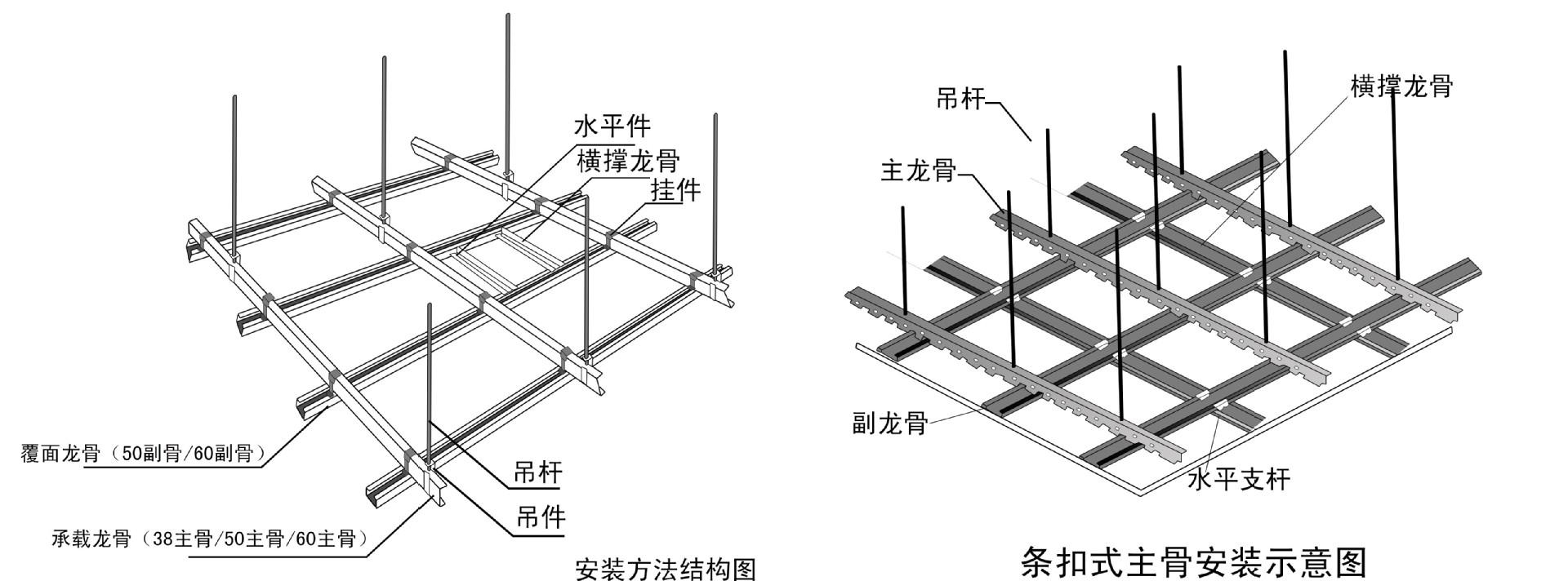

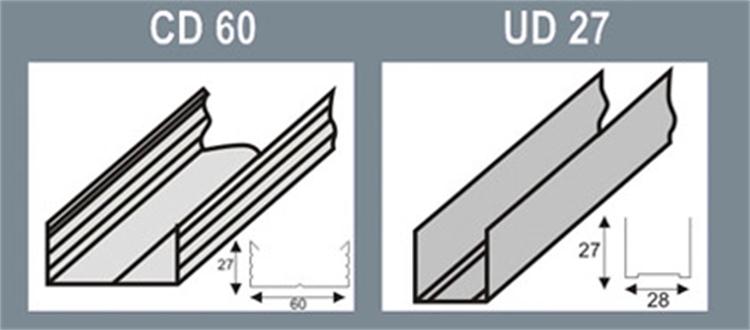

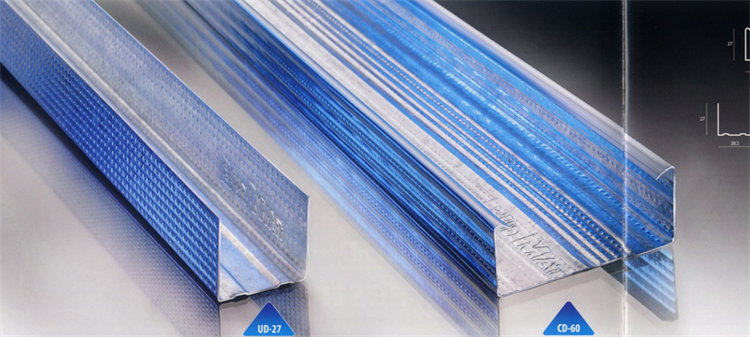

In modern society, metal Stud and Track quite popular all over the word. For one thing instead of wood, metal participation is more cheap and durable. For another thing, metal Stud and Track is easy to install and fast to make. Cater to the market requirement, Zhongtuo Stud and Track Roll Forming Machine was developed. Different with other roll forming machines, Stud and Track Roll Forming Machine supports both U shape and C shape metal track and stud making. So we also call this machine combined Stud and Track Roll Forming Machine.

Stud and Track Roll Forming Machine Decoiler System:

Passive uncoil pulled by roll forming system, support the Steel Coil and uncoil it in a turntable way.

| No : | Decoiler System Main Parameter : | |

| 1 | Loading capacity | 1.5T |

| 2 | Uncoiling width | 300mm |

| 3 | Inner diameter | 450-550mm |

Stud and Track Roll Forming Machine Roll Forming System:

In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, gear transmission, roller surfaces polishing, hard plating , heat treatment and galvanizational treatment. The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

| No : | Roll Forming System Main Parameter : | |

| 1 | Length of the main part | About 3000mm*1000mm*400mm |

| 2 | Weight of main part | 3 tons |

| 3 | Voltage | 380V/50HZ3Phase (as customer`s request) |

| 4 | Roller fixer | guide column |

| 5 | Frame | steel plate welded/ Memorial arch frame type |

| 6 | Frame thickness | 25mm |

| 7 | Drive mode | gear |

| 8 | Material of rollers | GCr12MoV |

| 9 | Material of shafts | 45# steel with tempering |

| 10 | Diameter of shafts | φ50mm |

| 11 | Number of rollers | 10 rollers |

| 12 | Main power | 5.5kw |

Double working lines on the machine to finish the two profiles. Change the feeding unit to make another profile, the cutting head can move left and right by hand!

Stud and Track Roll Forming Machine Automatic Cutting System:

Feature: Automatic cutting controlled by PLC. Ensure stability, precision and cutting speed. It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Components: It contains one set of cutting tools, one hydraulic tank and one cutter machine. Hydraulic station is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job. The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes and two sets of electromagnetism valves.

| No : | Cutting System Main Parameter : | |

| 1 | Material of blades | Gcr12MoV quenched |

| 2 | Power supply | hydraulic power |

| 3 | Frame | Pillar style with rack & pinion system |

| 4 | Stroke switch | non-contact photoelectric switch |

| 5 | Hydraulic motor Power | 3kw |

| 6 | Hydraulic oil: | 46# |

Stud and Track Roll Forming Machine Electric Control System:

1. Adopted PLC , transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

2. Equipped with movable switch , air break, radiator, transformer & electric leakage protector for operation convenience and safety.

Stud and Track Roll Forming Machine Products receiving table:

It adopts welded steel and supported roller to transmit the products.

Our Services

1. One year warranty, whole life technical support.

2. Installation & adjustment: We can take video for the customer and customer can also come to our factory, we can train customer how to install and adjust the machine.

3. Oversea service: the buyer should charge of visa, return ticket, food and accommodation overseas and USD 80/person/day salary.

Company Information

Cangzhou zhongtuo Roll Forming Machinery co., ltd as a manufacturer since 1996, we are specialized in manufacturing color steel forming machine, light keel machine, c&z purline machine, glazed tile forming machine, welded tube mill, steel structural floor panel roll forming machine and so on. We can provide you one station, non-stop service. Our machines have been exported to 90 countries, such as Canada, South Korea, Russia, Holland, Sri Lanka, Malaysia, India, Brazil as so on. Our company insists on the service aim: Quality First, Credit First. We believe that we can make the future cooperation and achieve win-win

Why choose to cooperate with us ?

1. We are professional manufacturer, we can produce best quality machine for you.

2. We have strong design ability, we can design machine as your requirements.

3. We have much experience for installation and training experience overseas.

4. We have successfully exported our machines to more than 90 countries.

5. We provide one year machine warrant and whole life technical support.

Contact us if you need more details on Stud Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Track Roll Forming Machine、Stud Track Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : C/U/ Channel & T Bar Roll Forming Machine > Ceiling Channel Roll Forming Machine