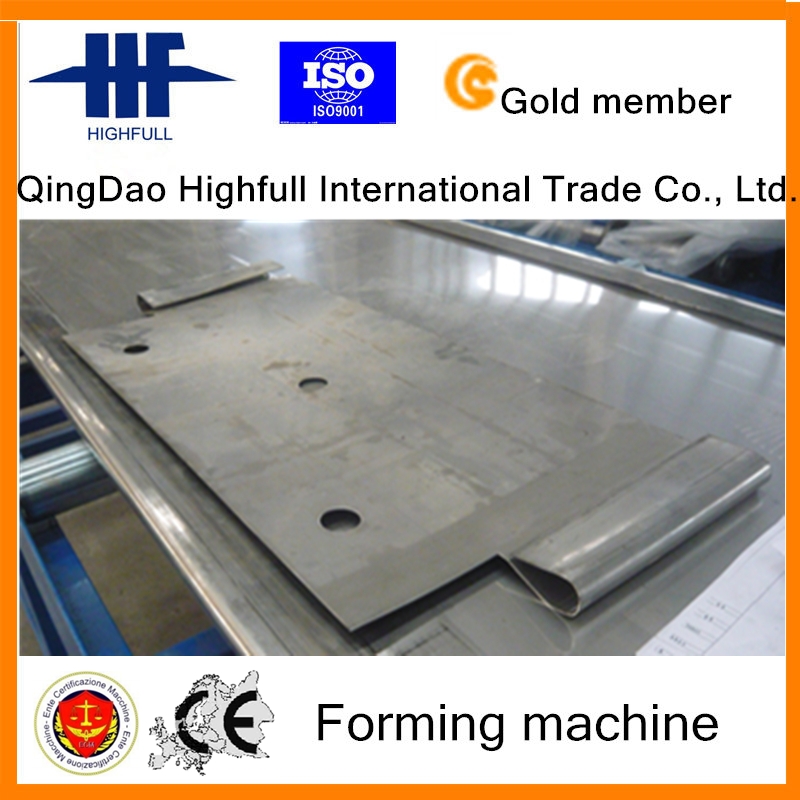

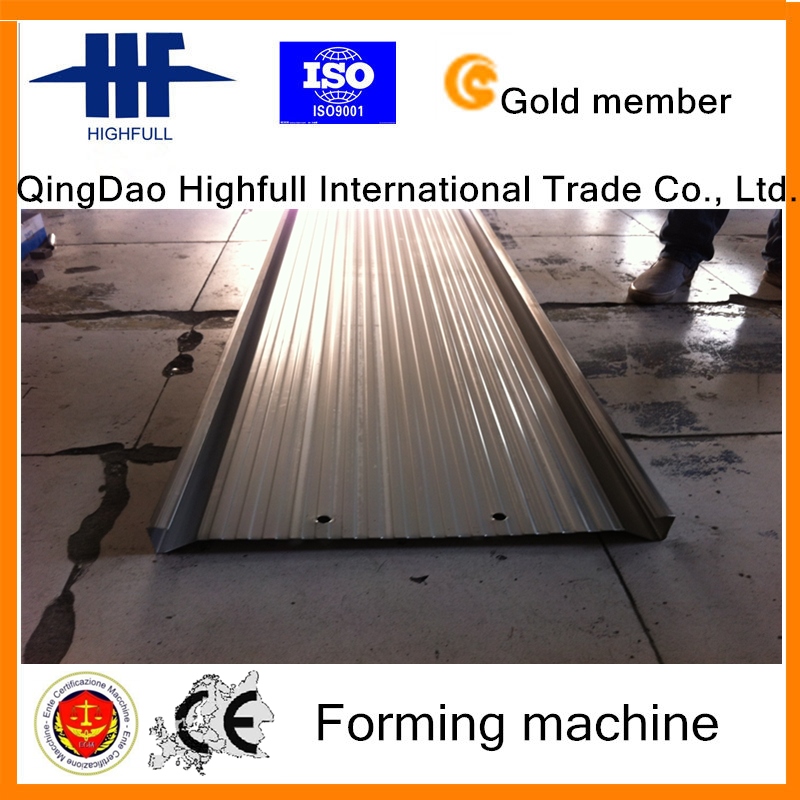

Anode Plate Roll Forming Machine of Environmental

Basic Info

Model No.: HIGHFULL

Product Description

Our products has feasures of

1. Nice appearance

2. High efficiency

3. Low noize and high quality.

4. Easy control.

1.technical process:

uncoil--leveling--roll forming--hydraulic punching--cutting--out table

2.machine components:

| S. N | equipment name | Quantity | Weight |

| 1 | hydraulic decoiler | 1 set | 8T |

| 2 | leveling machine | 1 set | 2T |

| 3 | punching machine | 1 set | 31T |

| 4 | main roll forming machine | 1 set | 28T |

| 5 | hydraulic cutting machine | 1 set | 1.5T |

| 6 | control system | 1 set | 0.1T |

| 7 | out tables | 2 units | 1T |

A. Coil inner diameter: 480mm--520mm

B. Max width of coiling: 1000mm

C. Max weight of loading: 8000kg

3.Main parts of production line

1.Suitable material | galvanized steel sheet,aluminum sheet,strip steel |

2.Installation Dimension (L*W*H): | 6.5m*1.5m*1.4m |

3.Main motor power | 22kw |

4.Hydraulic station power | 15KW |

5. The weight of decoiler | <8t |

6.Thickness of material | 1.2mm~1.5mm |

7.Diameter of principal axis | 90mm |

8.Material expand width | 1000mm |

9.Electric tension | 380V 3phase 50Hz or as the customer's requirements |

10.Material of roller | 40 Cr |

11.Controlling system | PLC |

12.Processing speed | 12m/min |

13.Processing precision within | 1.00mm (depend on design) |

14.Material of cutting blade | Cr12 mould steel with quenched treatment |

15.Kind of drive | 0.6 inch chain link bearing model |

16.Roller station | 22Rollers |

17.Roller material | high grade 45#steel; Cr12 quenching |

18. Leak frame load-bearing | 4.6T |

FAQ

What is main parameters?

1.Gear box and universal joint drive.

2.PLC control.

Is the sample available?

Yes,sample are available for you to test the quality.

Are the products tested before shipping?

All the products have to pass strict inspection before they go out.

Why choose us?

1.We are a factory manufacturing ,best production capability,best quality control,best service.

2.competitive price.

3.Best after-sale service.

4.Different types of roll forming machine,customers' own design is OK.

5.Super High quality.

6.Big production ability.

What is benefit will you bring?

Your client satisfied on the quality.

Your client continued orders.

You can get good reputation from your market and obtain more orders.

4.Our after-sale service:

Our products are widely used in various industrial factory ,beauty spot, holiday village building, hotel,exhibition ,easy steel building manufacturing ,and have features such as nice appearance. Contact us if you need more details on Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roll Forming Machine、Roll Forming Machinery. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Anode Roll Forming Machine